Improving Your Welding Abilities: Focus on Gauge Fillet Welds

Fillet Weld Style Methods: Enhancing Joint Efficiency and Appearance for Structural Honesty

In the realm of structural engineering and fabrication, the relevance of fillet weld layout techniques can not be overemphasized. By meticulously thinking about variables such as weld profile optimization, material choice, joint preparation methods, welding process performance, and aesthetic enhancement approaches, producers and engineers can achieve a harmonious balance in between capability and appearance in their bonded structures.

Weld Account Optimization

Achieving an optimum weld profile involves a meticulous factor to consider of aspects such as material thickness, joint configuration, welding setting, and preferred welding speed. Furthermore, the option of appropriate welding parameters, such as voltage, existing, and travel speed, is basic in regulating the shape and measurements of the fillet weld. Making use of innovative welding techniques, such as pulse welding or robot welding, can further improve the weld account to satisfy certain style demands and quality requirements.

In essence, weld account optimization is a fundamental facet of fillet weld design that straight influences the overall performance and reliability of welded joints in architectural applications.

Product Selection Considerations

When thinking about product selection for fillet weld design, the compatibility of the base metals is a critical variable affecting the architectural honesty of the joint. It is important to choose products that not only bonded together successfully yet also possess comparable mechanical buildings to make sure the lots is equally dispersed between the base and the weld steels. Welding materials with vastly different residential properties can bring about concerns such as tension focus, premature joint failure, or cracking.

Additionally, the setting in which the welded structure will certainly operate need to be taken into account when choosing products. Elements like rust resistance, temperature variations, and direct exposure to chemicals can all impact the long life and efficiency of the weld joint. By picking products that appropriate for the desired application and atmosphere, the overall resilience and dependability of the bonded joint can be considerably boosted.

As a result, thorough factor to consider of product compatibility and environmental variables is vital in guaranteeing the weld joint's toughness, durability, and overall structural integrity.

Joint Preparation Strategies

Taking into consideration the important duty material option click here to read plays in ensuring the architectural honesty of fillet weld joints, it is vital to execute precise joint prep work methods that maximize the link between the base steels. Joint preparation is a crucial step that directly influences the high quality and stamina of the weld.

In addition, tack welding the components in place before the last weld helps keep alignment and lessens distortion during the welding process. By carefully adhering to these joint prep work strategies, welders can improve the general efficiency and visual appeals of fillet weld joints while ensuring structural soundness.

Welding Refine Effectiveness

Efficient welding procedures are essential for attaining optimum efficiency and quality in fillet weld fabrication. One essential facet of improving welding process performance is picking the ideal welding strategy. Aspects such as product type, joint design, and welding placement have to be very carefully considered to identify the most appropriate approach. For example, procedures like gas metal arc welding (GMAW) and flux-cored arc welding (FCAW) are generally utilized for fillet welds because of their flexibility and rate (Gauge Fillet Weld).

Moreover, guaranteeing proper devices arrangement and upkeep is vital for efficient welding. Routine calibration of welding equipments, evaluation of consumables, and upkeep of soldering iron can protect against downtime and revamp, inevitably saving time and resources. In addition, utilizing knowledgeable welders with know-how in the details welding process being utilized can considerably influence efficiency. Well-trained welders are a lot more skilled at readjusting criteria, fixing issues, and keeping constant weld high quality.

Aesthetic Enhancement Methods

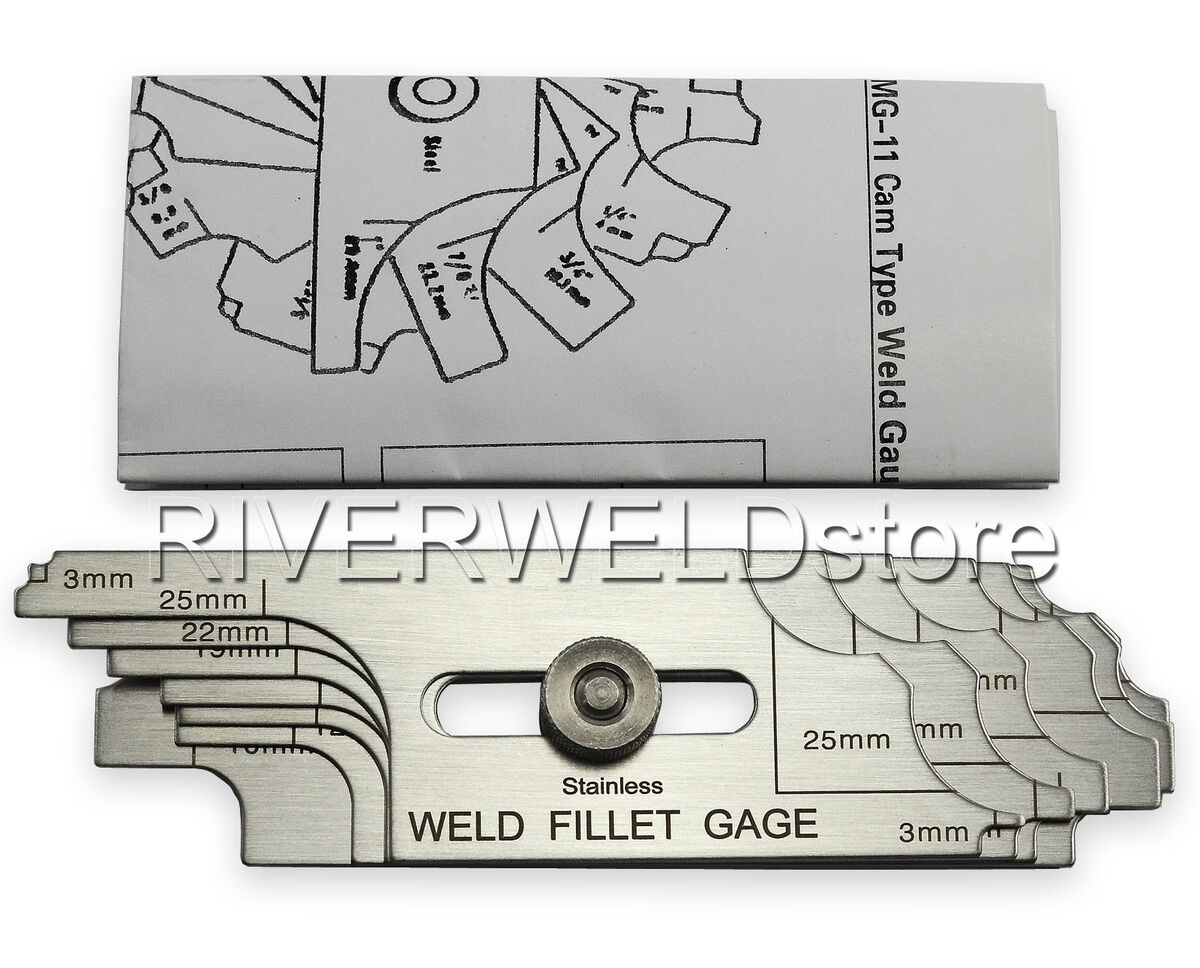

To enhance the high quality of fillet weld construction, executing aesthetic enhancement approaches can play a vital duty in ensuring precision and precision throughout the welding process. Aesthetic enhancement techniques include different you could try here strategies targeted at improving the appearance and high quality of fillet welds. One common technique is making use of back purging systems to remove oxidation on the backside of the weld, resulting in a cleaner, a lot more aesthetically pleasing surface. Furthermore, using appropriate lighting setups in the welding area can boost visibility, allowing welders to monitor the weld swimming pool and make sure regular grain development. Visual aids such as weld dimension evaluates and magnifying lenses can assist in evaluating weld profiles and dimensions accurately. The use of contrasting noting materials or temporary adding can help in lining up and placing the workpieces exactly prior to welding. By incorporating these visual enhancement techniques into the welding process, welders can accomplish not only structurally sound fillet welds yet also visually appealing results that meet market criteria.

Conclusion

Finally, optimizing fillet weld layout involves careful consideration of weld account, material selection, joint preparation, welding procedure effectiveness, and aesthetic improvement techniques. By carrying out these techniques, structural stability can be improved while additionally achieving aesthetic appeal. It is Home Page necessary to prioritize both performance and looks in fillet weld design to make sure the overall quality and durability of the joint.

By thoroughly considering variables such as weld profile optimization, material option, joint prep work techniques, welding process efficiency, and aesthetic enhancement methods, fabricators and designers can accomplish an unified balance between capability and look in their bonded frameworks.In the world of fillet weld design, enhancing the weld profile plays an important role in making sure structural stability and efficiency. The weld profile, which consists of the dimension and shape of the weld cross-section, directly influences the circulation of stress and load-bearing ability within the joint. It is crucial to select materials that not just weld together properly however likewise have comparable mechanical buildings to ensure the load is evenly distributed in between the base and the weld metals - Gauge Fillet Weld.In verdict, maximizing fillet weld style involves careful consideration of weld account, material choice, joint prep work, welding process efficiency, and visual enhancement methods